Services

Systems Integration & Process Automation

Automate and get systems working together for greater efficiency, reduced risk and better results.

Save on Energy

How would you like to cut your power costs by 25% or more? Let us see how we can help you create significant energy savings and take advantage of government incentive programs.

Axis network cameras

Get HD to 8K UHD image quality even in poor lighting conditions. Give plant operators ‘eyes’ on critical areas of your production processes and analytics that can improve your business.

Some of our past work

Case study: Canadian Mist whisky distillery

The situation

In this large distillery, old computers running past end-of-life software controlled even older automation equipment. Maintaining systems was challenging. There were frequent failures, downtime, high maintenance costs and an increasing risk of major catastrophic failure, potentially resulting in months of downtime.

Solution

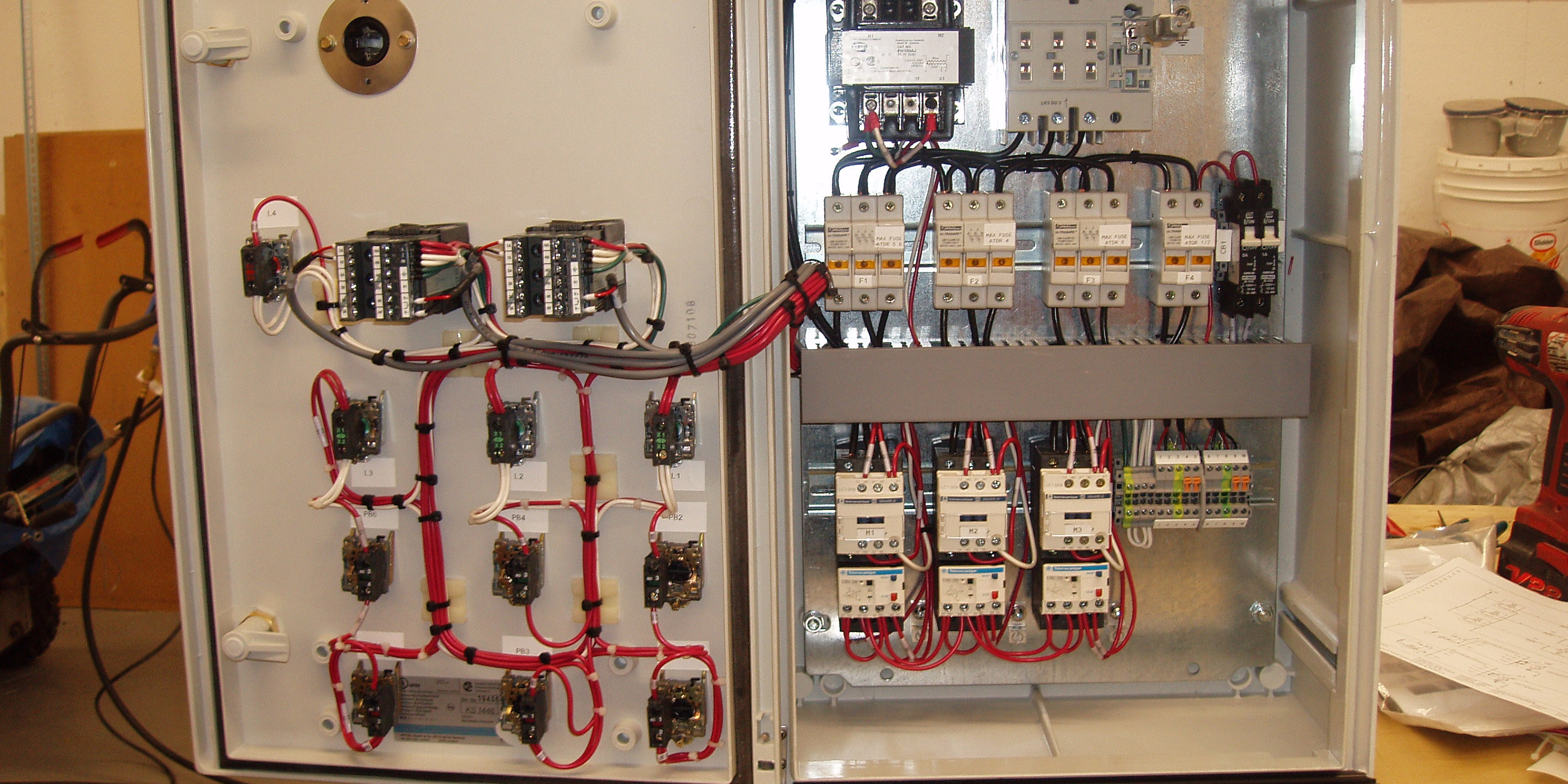

We installed brand new state of the art modern IT network infrastructure, a high availability resilient server that can withstand any failure in any component, including hard drives, processors, memory, etc. We put in new PLC automation equipment, rewired all of the new IO signals to the PLCs and designed a new SCADA graphical interface for interaction with plant automation equipment. We commissioned the system and trained staff. We also delivered the project on a much tighter timetable than expected.

Result

The distillery now has a modern system that will be well supported for decades to come. It is much more conducive to upgrades and improvements, as well as simpler to maintain. There are fewer outages; it is a stable, reliable, supportable platform. The extent of automation is greater and we granted the team remote access to the SCADA system as well as providing them with better diagnostic information. Graphical interfaces now depict interlock conditions, making it simple to diagnose root causes and quick to resolve. Our customer was very happy with our work and appreciated that we went above and beyond to meet an accelerated timeline.

Ask us about some of our other local client work:

- Areas municipalities

- Food processors

- Cider maker

- Auto parts manufacturer

- Agricultural product wholesaler

To find out how you can add efficiency and automation to your commercial/industrial processes, please contact us.

Case Study: Town of Bradford

The situation

The Town of Bradford sewage treatment plant needed to expand its capacity due to rapid population growth. Beach 1 Electric (our former name)won the tendered bid and handled all of the systems integration on the project.

The solution

This major plant upgrade involved significant new equipment, control panels, fibre optic networking, remote system access and a complete review of their alarming systems.

Result

Project managers were very pleased with our work. Where other contractors would have met the minimum requirements of the work detailed in the contract, we went well above and beyond those minimum requirements. As is always the case, we wanted to make sure that the customer was happy with the final solutions. We continue to do work on projects for the Town of Bradford – they now a longstanding, satisfied client.

Ask us about some of our other local client work:

- Areas municipalities

- Food processors

- Cider maker

- Auto parts manufacturer

- Agricultural product wholesaler

To find out how you can add efficiency and automation to your commercial/industrial processes, please contact us.

Case study: Town of Collingwood Sewage Treatment Plant

The situation

The Town of Collingwood’s wastewater treatment plant had three aeration blowers run by 100hp electric motors. During the summer they ran two of them continuously, and one in winter. The cost of the energy to run the blowers was at least half of the cost to run the entire plant. The Town had minimal information on the process, which limited their ability to make informed decisions on the regulation of airflow into those aeration basins.

The solution

We provided motorized automated valves to cut back on air supply to the blowers and to regulate how much air went into all nine cells of the aeration system, we added dissolved oxygen sensors to monitor oxygen levels, air pressure monitoring and air flow measurement. We installed PLC equipment and upgraded their SCADA system and put programming in place to automate all of this. Then we were able to run the right number of blowers depending on what is required, regulate the air pressure in the main header, able to regulate the air flow to each of the six cells of the aeration system in order to maintain the ideal dissolved oxygen level at all times.

The result

The Town of Collingwood now has optimized airflow, consistent dissolved oxygen going to feed aerobic microbes. As the demand increases due to more sewage coming in or as it decreases due to colder temperatures, the equipment ramps up and down as needed, starting and stopping blowers as needed, regulating the right amount of air to each area. The end result is substantial energy savings and better control of the process. The project easily paid for itself within two years.

Ask us about some of our other local client work:

- Municipalities

- Food processors

- Cidery

- Auto parts manufacturer

- Agricultural product wholesaler

To find out how you can add efficiency and automation to your commercial/industrial processes, please contact us.